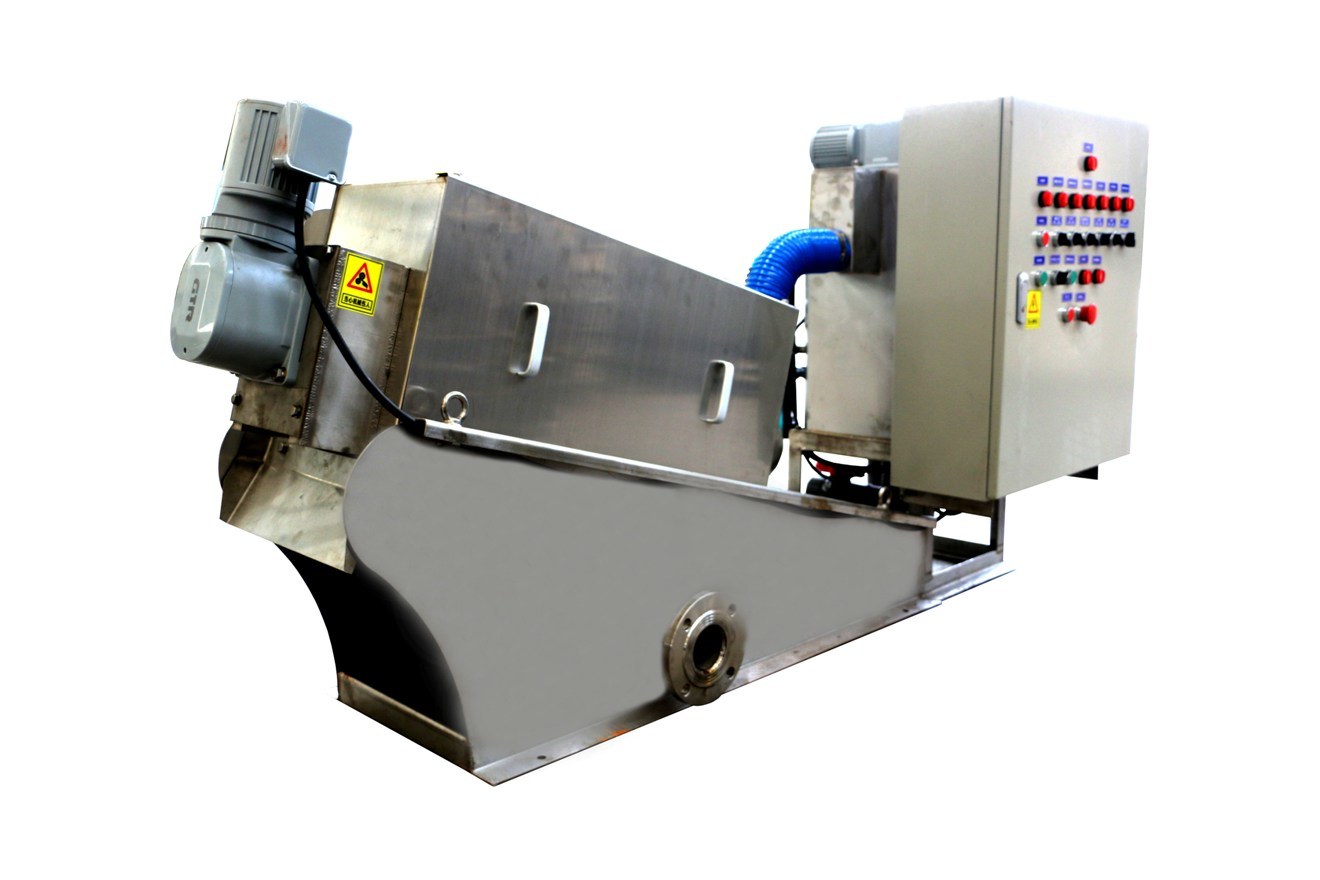

In the process of waste water treatment, water-containing sludge of different properties is generally produced. The sludge dewatering equipment mainly reduces the water content of the sludge, and reduces the sludge volume, thereby bringing convenience to the subsequent treatment or disposal of the sludge. With the advantages of energy saving, stability, and high degree of automation, the screw press sludge dewatering machine, also named Multi-disc Screw Dehydrator, occupies a place in the current sludge dewatering operation in the wastewater treatment industry, and it is still quickly recognized and accepted by the market.

This machine is a kind of economic and environmental friendly sludge dewatering equipment. It is a new type of sludge extrusion dewatering equipment by using the principle of screw extrusion, through the strong squeezing force generated by the change of screw diameter and screw pitch, and the tiny gap between the floating ring and the fixed ring, to realize solid-liquid separation.

Sludge dewatering equipment is not intended to treat the sludge or liquid but; it only separates the liquid components & solid components so it will get easier & cost-effective to handle the separate phases of the disposal. Once the Final sludge has been dewatered, then the liquid is treated in ETP/STP & solid sludge is disposed.

Application:

- Municipal Sewage

- Petro Refining

- Leather Making

- Painting and Drying Paper

- Coalification dressing

- Biochemical Pharmacy

- Steel Pickling

- Chemical Sugar

- Food Processing

Advantage:

- Low operation cost: Below 40% of belt press and 20% of centrifuge

- Power Saving: Less than 5% of centrifuge

- Saving Drugs: Saving around 60%

- Compact: Saving more than 60% of the investment for dehydration room

- Non Clogging: Processing fats and Oils and fiber sludge perfectly

Key Features:

- Simple processing, Low investment, energy efficient in high efficient sludge dewatering.

- Supports reduction in moisture content of sludge significantly.

- Allows easier handling of industrial wastes.

- Unique flocculation agent make sludge dewatering easier.

- Process includes sludge conditioning, bag filling and draining cycles that are controlled through integral control panel.